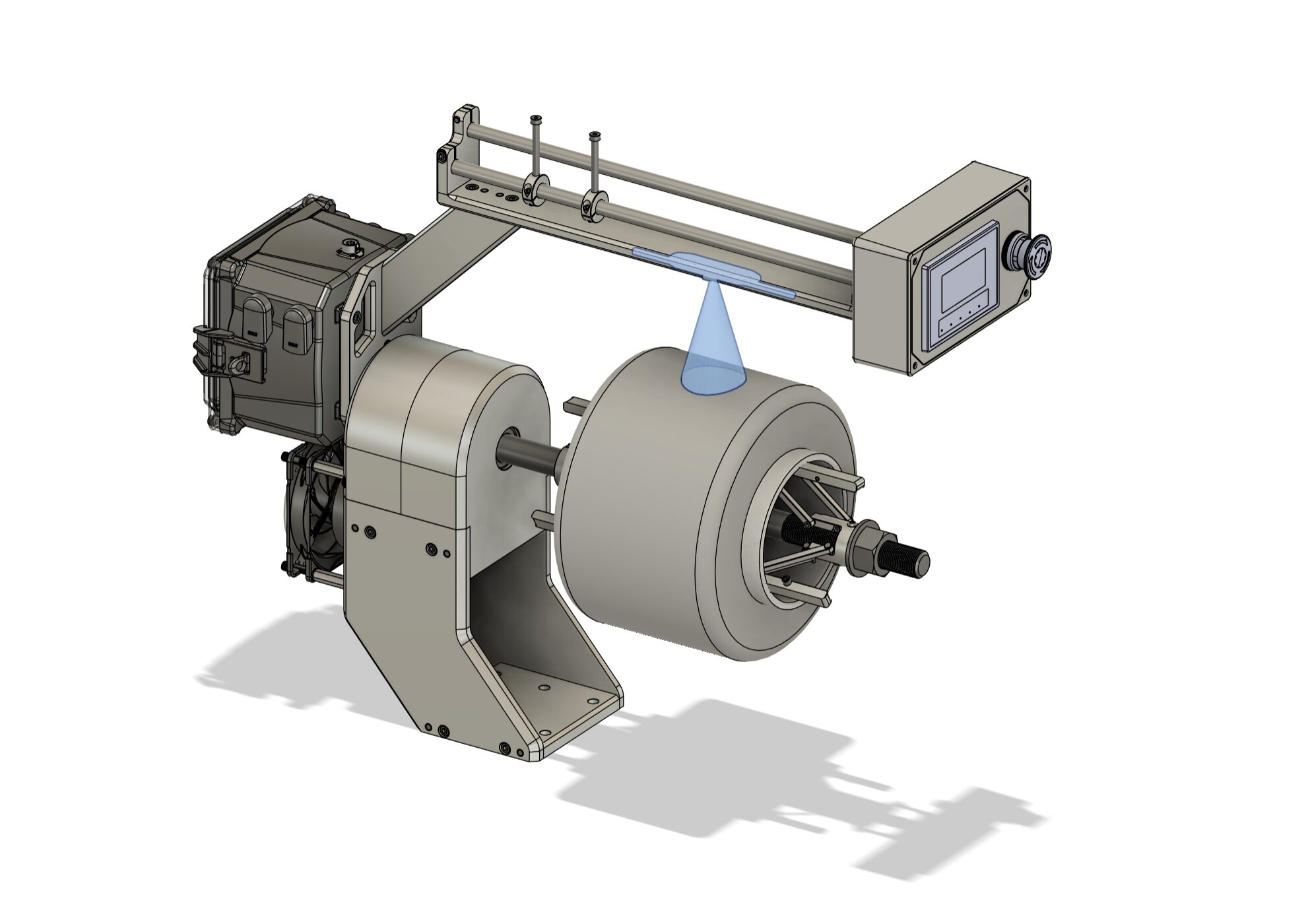

Fiber Creel Tensioner: Same Tension Different Speeds

In the composite’s world, tension is everything. No matter what process you have from thermosets to thermoplastics, perfect tension is very important. Most processes take bulk fiber spools which then pay-off though the impregnation process of infusing them with the necessary binding agent for the end product. The tension ensures the manufacturing process is as accurate as possible. If the tension varies, the impregnation quality might change leading to downstream failures of the product.

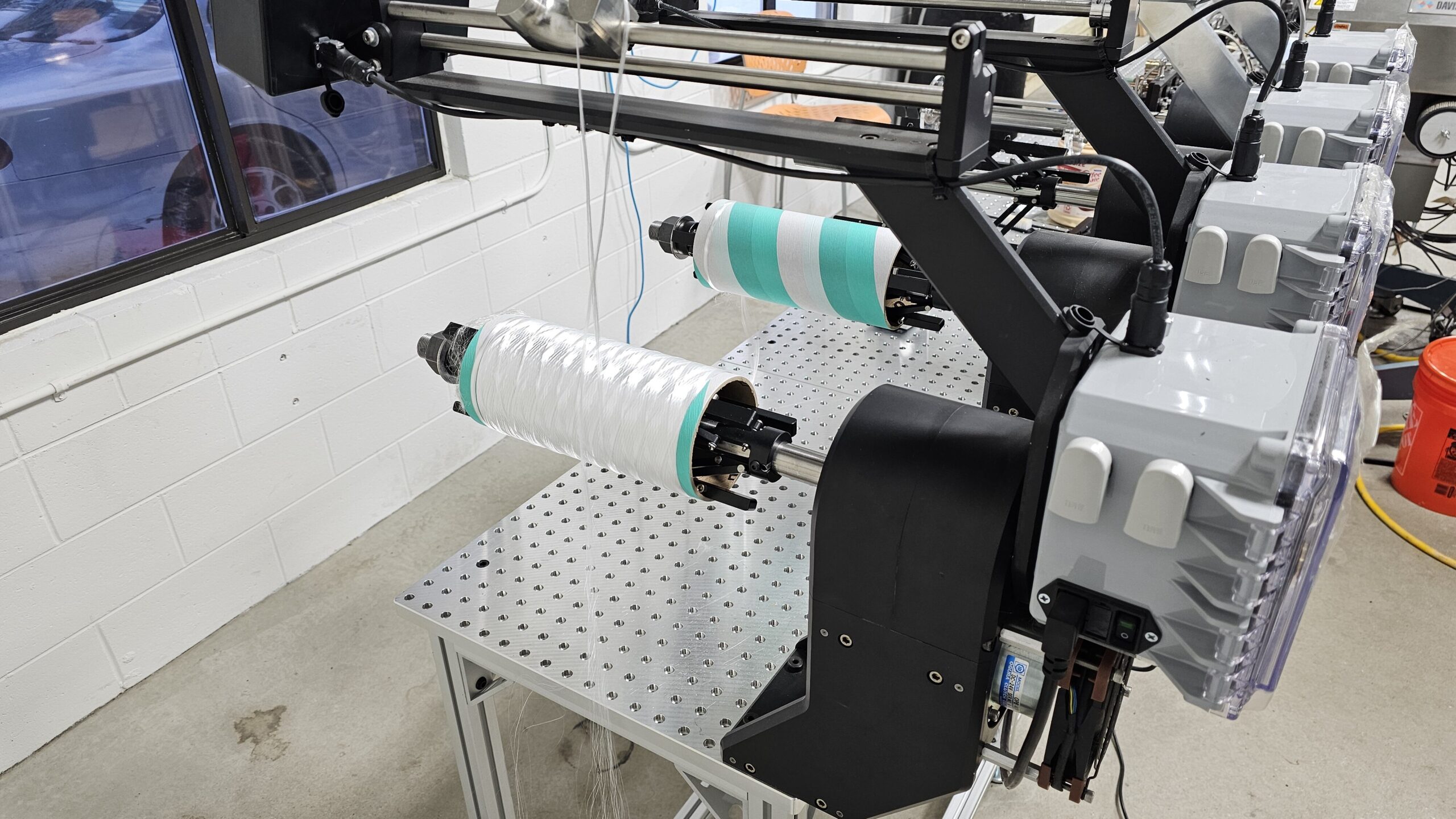

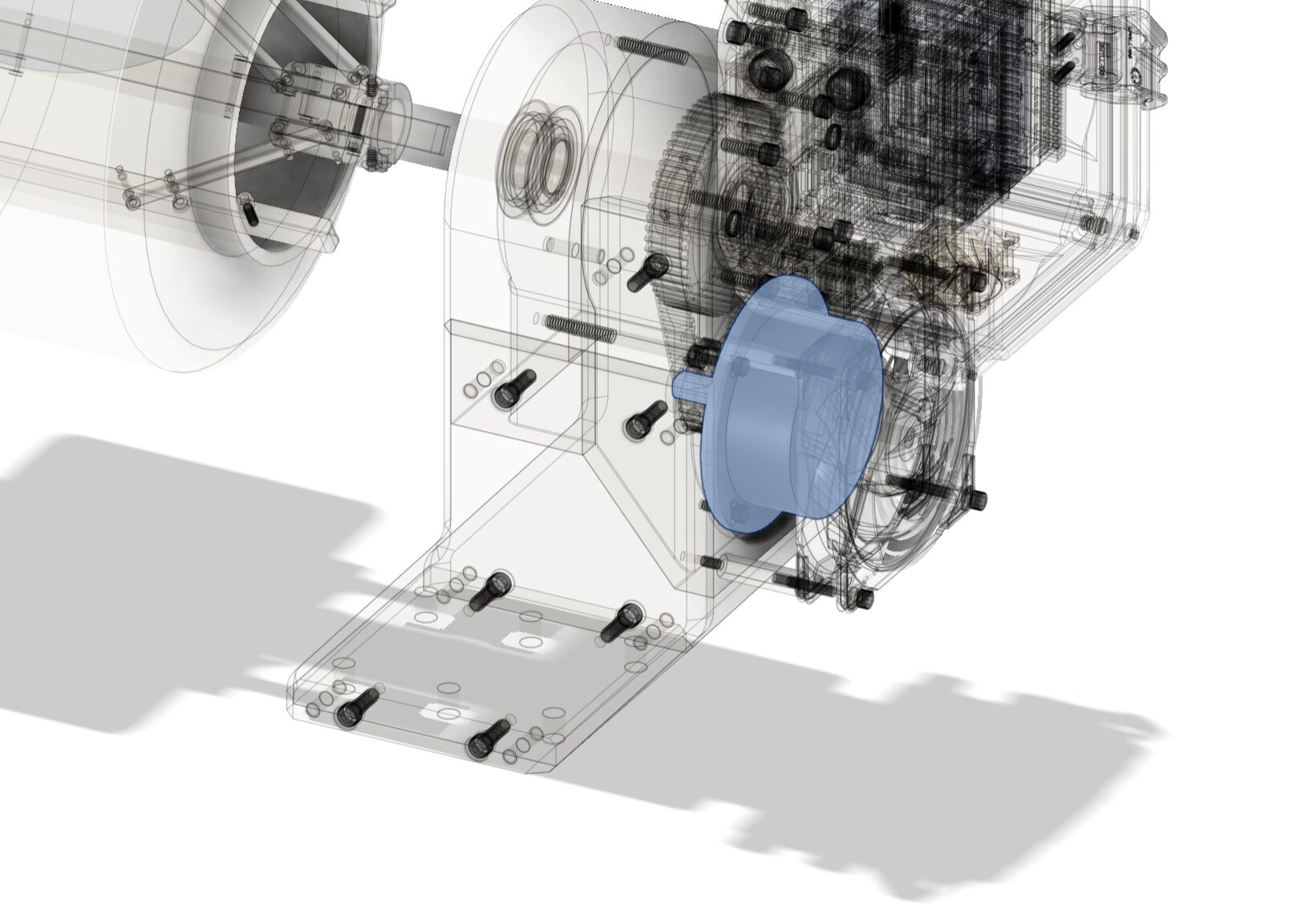

Self-Centering: Expansion is key

Having an easy to change system which can adapt to different size spools is a very nice quality of life mechanism. I designed an expansion spool holder which can hold spools with a 3″-7″ ID. This covers all of the industry stand packages making it a “one size fits all” solution. The mechanism also allows for the spools to be mechanically centered any time it was tightened. This ensures the system is accurate during operation.

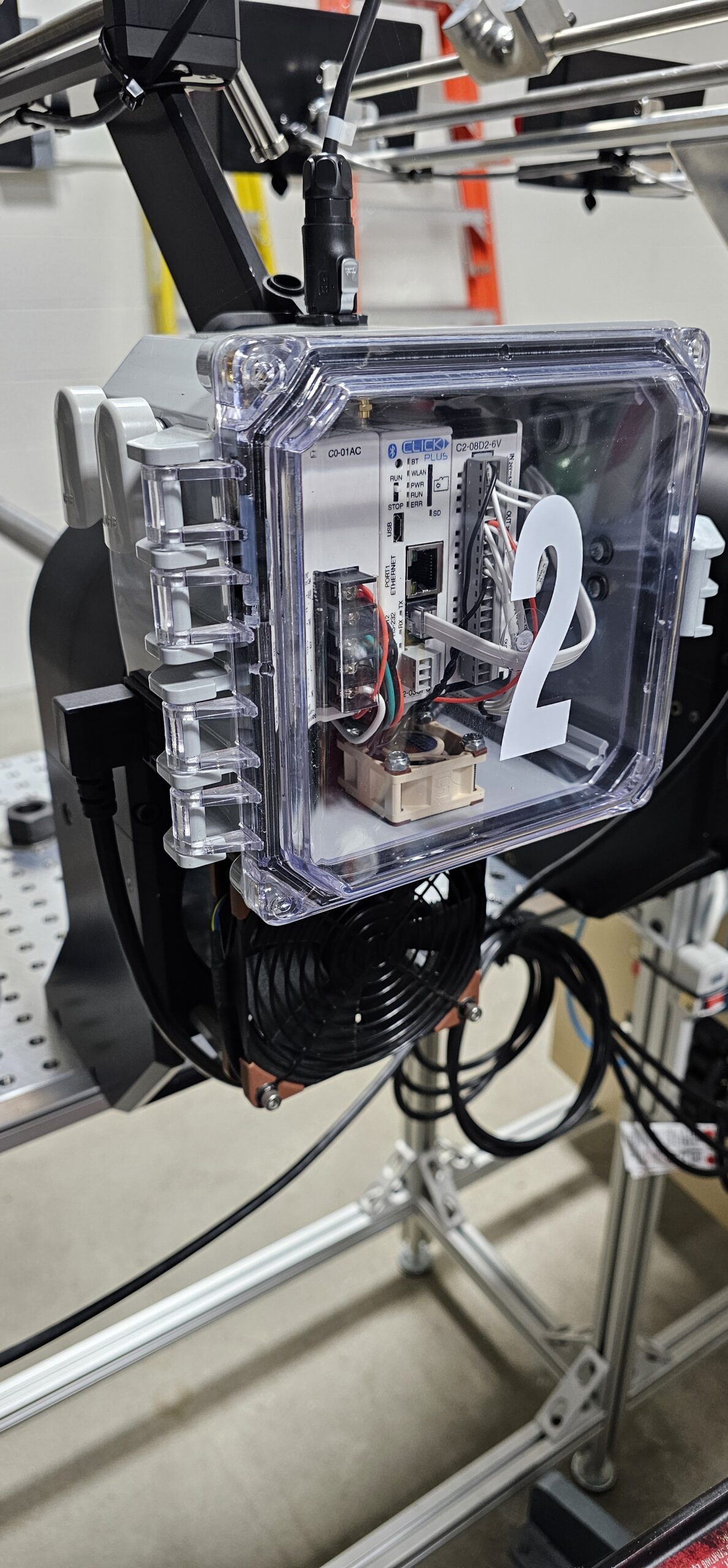

PLC: Industrial Logic for Easy Integration

Working on the electronics architecture it was an easy choice to integrate a PLC controller. Making it easy for future integration with other equipment and long-lasting reliability. Many industrial pieces of equipment operate with PLC controls. Keeping the electronics enclosure small was difficult as most PLC enclosures end up being large cabinets. We did not want this as each tensioner unit can be moved around and run independently.

Diameter: Sensors Allow for Change

With the design choices made, the fiber pulls from the outside of the spool. This means as the material is used, the diameter of the spool changes smaller. In order to keep constant and accurate fiber tension, the system had to compensate as the resistive force was applied through the shaft. We were able to develop and use a time-of-flight infrared distance sensor to measure the distance to the spool surface, giving us the ability to continuously adjust the resistive force being applied to the shaft keeping the desired back tension as the fiber is used.

Force: Magnetic Particle Brakes are Awesome

One of the coolest pieces of hardware is the magnetic particle brake. It uses very little power to change the rotational resistance of the shaft while also generating very little heat, unlike traditional friction braking systems. The resistive force also remains constant no matter the speed at which you pull the fiber off the spool, allowing it to be accurate even if your process is slow or fast. The magnetic particle brake is perfect for application where constant slip is need and is capable of thousands of hours of operation.

Start Your Project

Don’t miss out on the chance to turn your ideas into reality. Partner with PFM Design today for innovative product development.